Cutting Simulation

We have an exemplary record of achievements through our consultation process.

We will deliver high-standard products based on your requirements and our expertise.

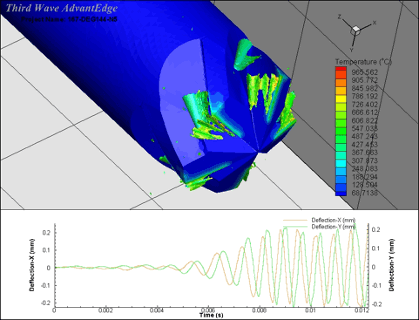

Cutting Simulation Case 1

Cause

After we asked the client about the details of this tool, we assumed that reducing the cutting load might be a clue to the solution. Based on our experience, we propose a plan to secure axial squeeze by reducing the number of blades and using twists to reduce the cutting load.

Solution

Since it is not an inexpensive tool, we modeled the defective tool and performed a cutting simulation to ensure our possible solution would work. Finally, we used the output result of the simulation as the absolute value. So, we modeled the tool of the improvement plan, performed the cutting simulation, compared the output result with the original tool relatively, and confirmed that the outcome is an improvement. After completing these steps, we began to manufacture the tool.

Outcome

We were successfully able to produce the tool with high quality without any chatter marks.

Previous

Next

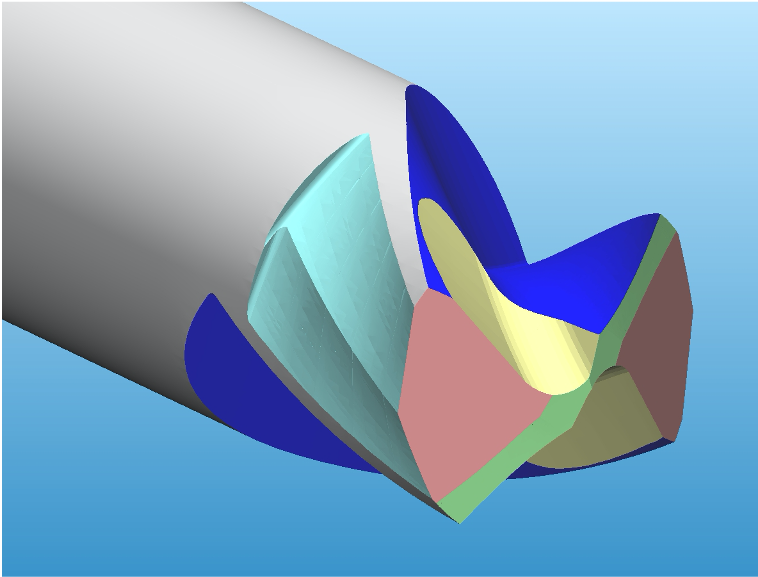

Cutting Simulation Case 2

Challenge

A client consulted us about a problem: when they processed a curved workpiece, the tool was out of place, and the processing point went off.

Solution

Our client and we exchanged ideas together and referred to conventional tools. As a result, we modeled and simulated four types of tools with different tip shapes.

Outcome

By observing the behavior of the XY tool in a graph, we selected the shape that the tool does not carry when entering the curved surface of the work. After that, we finally manufactured the tool equipped with atari.

Previous

Next

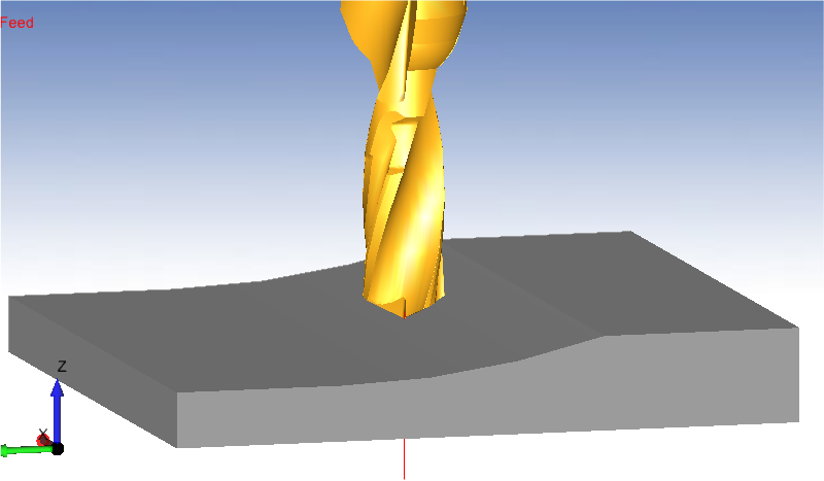

Cutting Simulation Case 3

Challenge

A point marked red circle is a chip which is likely to occur after processing.

Solution

We found out the cause of the problem with this tool by checking the difference between the two types of tools through the cutting simulation.

Outcome

We acquired the visible expectation that the facet drill bit created at the process of uppercut stuffed up to the surface of the slot side, and it is cutting with stuck while it is in uppercutting process.

Previous

Next